Mail: htcrusher@hamachine.com

Telephone: 008618838076345

Links: YOUTUBE TWITTER FACEBOOK

Introduction

Basalt is a common rock found abundantly in the Singapore region. It is formed from volcanic eruptions and has unique properties that make it suitable for various industrial applications. One such application is the use of basalt as a raw material for metal crusher technology. In this article, we will explore the metal crusher technology used for processing basalt raw materials in Singapore.

Metal Crusher Technology

Metal crusher technology is a type of equipment used to crush or break down large pieces of metal into smaller sizes. This technology is widely used in industries such as mining, construction, and recycling. The metal crusher technology used for processing basalt raw materials in Singapore is specifically designed to handle the unique properties of basalt.

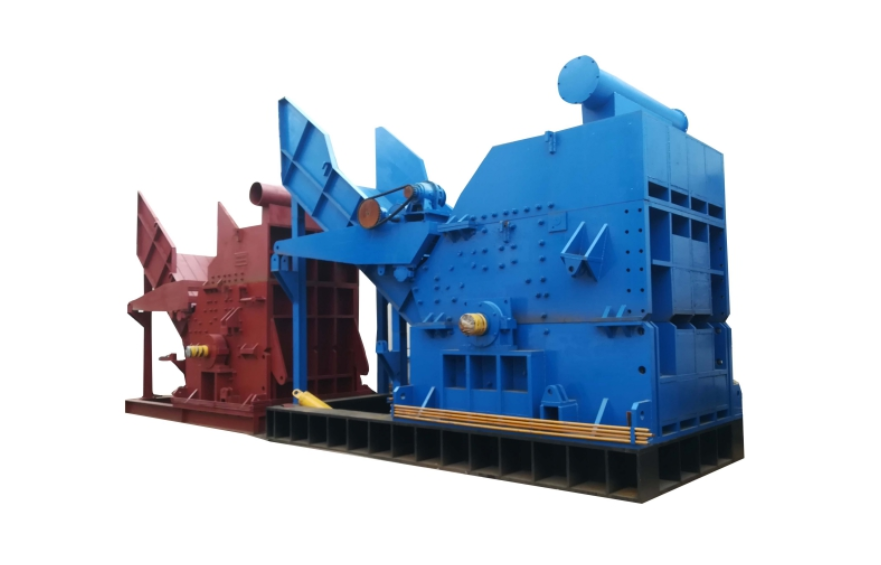

The Metal Crusher Machine

The metal crusher machine used for processing basalt raw materials in Singapore is a high-performance machine that can efficiently crush large pieces of basalt into smaller sizes. The machine consists of several components, including a feeding hopper, crushing chamber, rotor, hammer, and screen. These components work together to ensure that the basalt is crushed to the desired size quickly and efficiently.

Feeding Hopper

The feeding hopper is the first component of the metal crusher machine. It is responsible for feeding the basalt raw materials into the crushing chamber. The feeding hopper is designed to handle large quantities of basalt and ensure that the material is fed into the machine at a consistent rate.

Crushing Chamber

The crushing chamber is where the actual crushing takes place. It is made up of two plates that are positioned opposite each other. The plates are designed to withstand the high pressure generated during the crushing process. As the basalt enters the crushing chamber, it is crushed between the plates by the rotating hammer.

Rotor

The rotor is a crucial component of the metal crusher machine. It is responsible for driving the hammer that crushes the basalt. The rotor is powered by an electric motor and can rotate at high speeds to generate the necessary force required to crush the basalt.

Hammer

The hammer is another essential component of the metal crusher machine. It is attached to the rotor and is responsible for crushing the basalt. The hammer is made of high-quality materials that can withstand the impact forces generated during the crushing process.

Screen

The screen is the final component of the metal crusher machine. It is responsible for separating the crushed basalt from the larger pieces. The screen is made of a durable material that can withstand the wear and tear caused by the crushed basalt.

Conclusion

In conclusion, the metal crusher technology used for processing basalt raw materials in Singapore is a high-performance machine that can efficiently crush large pieces of basalt into smaller sizes. The machine consists of several components, including a feeding hopper, crushing chamber, rotor, hammer, and screen. These components work together to ensure that the basalt is crushed to the desired size quickly and efficiently. With its unique properties, basalt is an excellent raw material for various industrial applications, and the metal crusher technology used in Singapore plays a crucial role in processing this valuable resource.

Copyright © hengtong machinery Privacy Policy