Mail: htcrusher@hamachine.com

Telephone: 008618838076345

Links: YOUTUBE TWITTER FACEBOOK

Introduction

Armenia, a country nestled at the crossroads of Europe and Asia, is known for its rich history, stunning landscapes, and resilient culture. However, like many developing nations, Armenia faces significant challenges in managing industrial waste and fostering sustainable development. One such challenge is the disposal of coal gangue, a byproduct of coal mining that traditionally contributes to environmental pollution. This article explores an innovative solution: using coal gangue in brick production as a means to address waste management issues while promoting sustainable construction practices in Armenia.

The Problem with Coal Gangue

Coal gangue, also known as coal refuse or overburden, consists of rocks, dirt, and other materials that are removed during the extraction of coal. In Armenia, the coal industry has historically generated vast amounts of coal gangue, which often ends up in landfills or is left in large piles near mining sites. This not only occupies valuable land but also poses serious environmental risks, including soil and water contamination and the emission of harmful gases.

The Concept of Using Coal Gangue in Brick Production

The idea of using coal gangue in brick production is rooted in the principles of circular economy and waste valorization. By incorporating coal gangue into brick-making processes, we can transform a waste product into a valuable resource, thereby reducing environmental pollution and conserving natural resources.

Advantages of Using Coal Gangue in Brick Production

1. Environmental Benefits: Utilizing coal gangue in brick production helps to mitigate the environmental impact of coal mining. It reduces the volume of waste sent to landfills and minimizes the need for raw materials like clay, which requires significant energy and resources to extract and process.

2. Economic Benefits: The use of coal gangue can lower the cost of brick production. Since coal gangue is a waste product, it is available at little to no cost, making it an economically viable alternative to traditional raw materials. Additionally, the creation of a market for coal gangue can provide economic opportunities for local communities involved in its collection and processing.

3. Improved Brick Quality: When properly processed and incorporated into brick formulations, coal gangue can enhance the physical and mechanical properties of bricks. Studies have shown that adding coal gangue can improve the compressive strength, durability, and thermal insulation properties of bricks, making them more suitable for construction purposes.

Implementation in Armenia

Step 1: Research and Development

The first step towards implementing this innovation in Armenia is conducting comprehensive research and development (R\u0026D). This involves studying the composition and properties of locally available coal gangue, as well as experimenting with different formulations and processing techniques to optimize its use in brick production. Collaboration between academic institutions, research organizations, and the brick manufacturing industry is crucial at this stage.

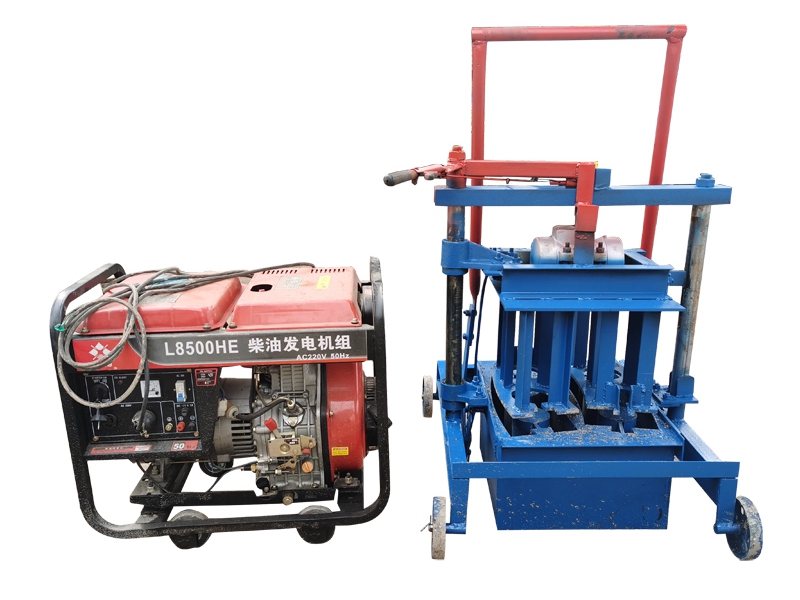

Step 2: Setting Up Pilot Projects

Once the R\u0026D phase yields promising results, the next step is to set up pilot projects. These projects should be established in collaboration with local brick manufacturers to test the feasibility and scalability of using coal gangue on a larger scale. Pilot projects will help identify potential challenges and fine-tune processes before full-scale implementation.

Step 3: Policy Support and Regulations

Government support and favorable regulations are essential for the successful adoption of this innovation. The Armenian government can play a pivotal role by providing incentives such as tax breaks, subsidies, and grants to encourage brick manufacturers to adopt coal gangue. Additionally, establishing quality standards and guidelines for the use of coal gangue in brick production will ensure consistency and reliability.

Step 4: Awareness and Training

Creating awareness among stakeholders, including brick manufacturers, builders, and consumers, is vital for the widespread acceptance of coal gangue bricks. Educational campaigns and training programs can highlight the environmental and economic benefits of using these bricks. Training workshops for workers involved in the production process will ensure that they have the necessary skills and knowledge to work with coal gangue effectively.

Step 5: Monitoring and Evaluation

Continuous monitoring and evaluation are crucial to assess the performance and impact of using coal gangue in brick production. Regular inspections, quality control measures, and feedback mechanisms will help identify any issues early on and make necessary adjustments. Long-term studies should also be conducted to evaluate the durability and performance of coal gangue bricks in real-world construction applications.

Conclusion

The innovative use of coal gangue in brick production presents a unique opportunity for Armenia to address its waste management challenges while promoting sustainable development. By harnessing the potential of this waste product, Armenia can reduce environmental pollution, conserve natural resources, and create economic opportunities. With concerted efforts from the government, industry, and academia, this innovative approach can pave the way for a greener and more sustainable future for Armenia's construction sector.

Copyright © hengtong machinery Privacy Policy