Mail: htcrusher@hamachine.com

Telephone: 008618838076345

Links: YOUTUBE TWITTER FACEBOOK

Introduction:

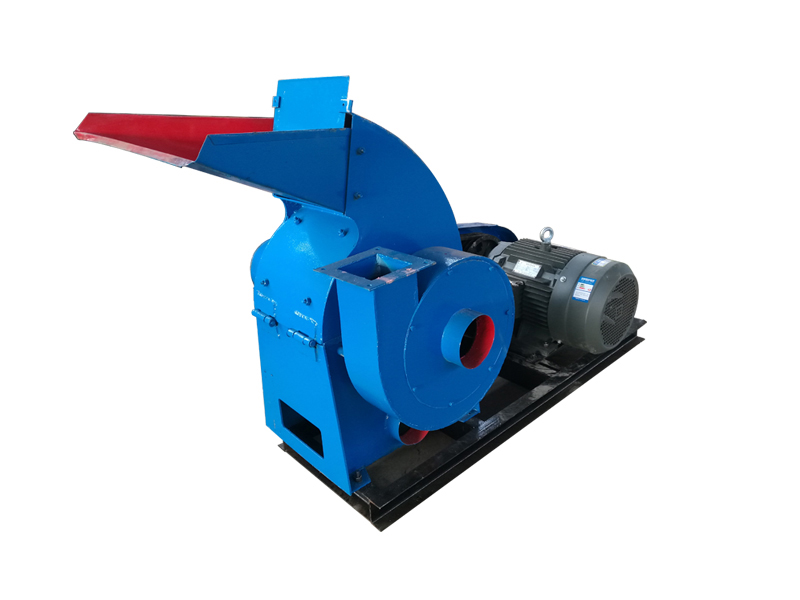

Palestine's tobacco industry is a vital sector, contributing significantly to the country's economy. However, the process of crushing tobacco stems, an essential step in the production of cigarettes, has been plagued with efficiency issues. The traditional crushers used in the industry struggle to handle the tough and fibrous nature of tobacco stems, leading to downtime and increased maintenance costs. This article explores how the introduction of aluminium ore can enhance the efficiency of tobacco stem crushers in Palestinian industries.

Aluminum Ore: A Game Changer for Tobacco Stem Crushers

Aluminum ore, a naturally occurring mineral, has emerged as a potential solution to the efficiency problems faced by tobacco stem crushers. The unique properties of aluminium ore make it an ideal material for enhancing the performance of these machines. Here are some ways in which aluminium ore can improve the efficiency of tobacco stem crushers:

1. Increased Durability:

Aluminium ore is known for its high durability and resistance to wear and tear. By incorporating aluminium ore into the construction of tobacco stem crushers, manufacturers can create machines that are better equipped to handle the tough and fibrous nature of tobacco stems. This increased durability reduces the need for frequent maintenance and repair, ultimately improving the overall efficiency of the crushing process.

2. Improved Cutting Ability:

The hardness of aluminium ore makes it an excellent material for creating sharp cutting edges. When used in the blades of tobacco stem crushers, aluminium ore can provide a more efficient and precise cutting action. This leads to a faster crushing process and a higher-quality end product, benefiting both manufacturers and consumers.

3. Reduced Energy Consumption:

Due to its lightweight nature, aluminium ore can help reduce the energy consumption of tobacco stem crushers. Machines constructed with aluminium ore require less energy to operate, leading to cost savings for manufacturers and a reduced carbon footprint for the industry as a whole.

4. Corrosion Resistance:

Aluminium ore is highly resistant to corrosion, making it ideal for use in environments where moisture and other corrosive substances are present. This resistance ensures that tobacco stem crushers constructed with aluminium ore remain functional and efficient even in challenging conditions, further enhancing their overall performance.

Conclusion:

The introduction of aluminium ore into the construction of tobacco stem crushers has the potential to revolutionize the Palestinian tobacco industry. By improving the durability, cutting ability, energy efficiency, and corrosion resistance of these machines, manufacturers can achieve higher levels of productivity and quality while reducing costs and environmental impact. As the industry continues to evolve, the adoption of aluminium ore and other innovative materials will be crucial for maintaining competitiveness and sustainability in the global market.

Copyright © hengtong machinery Privacy Policy