Mail: htcrusher@hamachine.com

Telephone: 008618838076345

Links: YOUTUBE TWITTER FACEBOOK

Introduction

The waste paint bucket crusher feeds the steel from the inlet into the machinery inside and crushes the metal materials in the cabin of the crusher. When crush the metal materials, the screen fixed in the bottom of the crusher, and the crushed metal particles will come out from the discharge port when the size reaches to the screen size.

The texture of the waste paint bucket crusher blades adopts type 63 manganese. Usually the design of the cutter is a row of blades and a row of hooks, which is more conducive to crushing metal and have faster effect as well.

Features

1. Gear motor drive.

2. The mating type blades are used to completely crush cans.

3. Select the special blade, the blade hardness not less than HRC55.(The HRC hardness for file is 51 degree. )

4. The crusher has strong structure and dense type stiffener plate to ensure strong cabinet.

5. Automatically control system, safe and convenient.

6. Various parts of the crusher body are coated with security identification and safety labels.

7. The conveyor belt is equipped to feeding the materials which improves the production efficiency.

Application Ranges

The nick names of the waste paint bucket crusher are steel scrap crusher, color steel tile crusher, bicycle crusher, motorcycle crusher and car shell crusher etc. The crushing material metal of crusher includes Sprite cans, lulu cans, red bull cans, and coke cans. It is not only can crush drink cans, but also can crush paint cans, machine oil tank and so on. The crushed material is very easy to carry and convenient to steelmaking. The time of feeding steel is also reduced a lot.

Working Principles

In the crushing process, external pressure pressed on the solid includes rolling, clipping, impact, grinding. Pressure rolling is mainly used in the coarse crusher, suitable for hard material and bulk material crushing; Clipping is mostly used in fine grinding, suitable for crushing the ductile material; Impact is mostly used in the crusher, fine grinding, super fine grinding, and suitable for crushing the brittle material; Grinding is mainly used in the fine grinding, super fine grinding, and suitable for crushing the small pieces. The actual crushing process is often conducted with the effect of several forces at the same time.

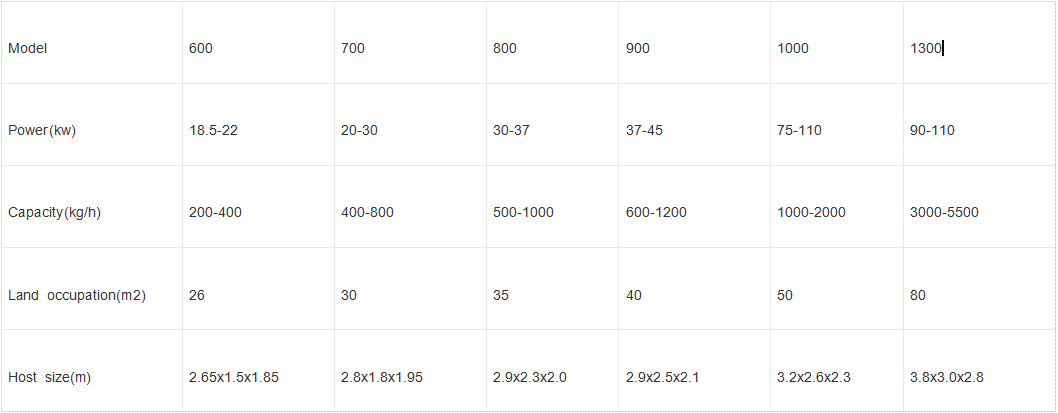

Parameter of Metal Cusher

Services for Metal Cusher

ü Professinal Technical consultation 24-hour onlineservice.

ü Free designing, choosing suitable equipment for you.

ü Hot-selling products, finished machine in stock, Shorten the leadtime and let the goods reach you earlier.

ü Support online orders, you can get 100% full pretection & credit insurance !

ü Continuous technical support to help you solve technical problems encountered during installation and commissioning.

ü One year warranty of whole machine, the host damage is directly replaced by a new machine for free!

FAQ

Q1.How long is the warrenty of your equipments? Does your company supply the spare parts?

The warranty period of crusher equipments is one year. Yes, we supply the spare parts for you at lowest cost and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: For providing you the appropriate equipment model we need to know the following information:

1.What is the raw material to be processed?

2.And maximum feeding size of raw material?

3.What is the required output size after crushing?

4. How many tons per hour do you want?

Q3.Can you test our samples?

Yes. You can send your samples to us for test and analysis.

Q4. If I need the complete crushing plant can you help us to build it?

Yes, we can help you combine a complete crushing line and give you related professional advice as long as you need. We had already build many mining projects in China & Overseas.

Copyright © hengtong machinery Privacy Policy